The abbreviation ESD is derived from the English and stands for "electrostatic discharge". These are voltage breakdowns that occur due to high potential differences. Consequently, there is a short, high current flow.

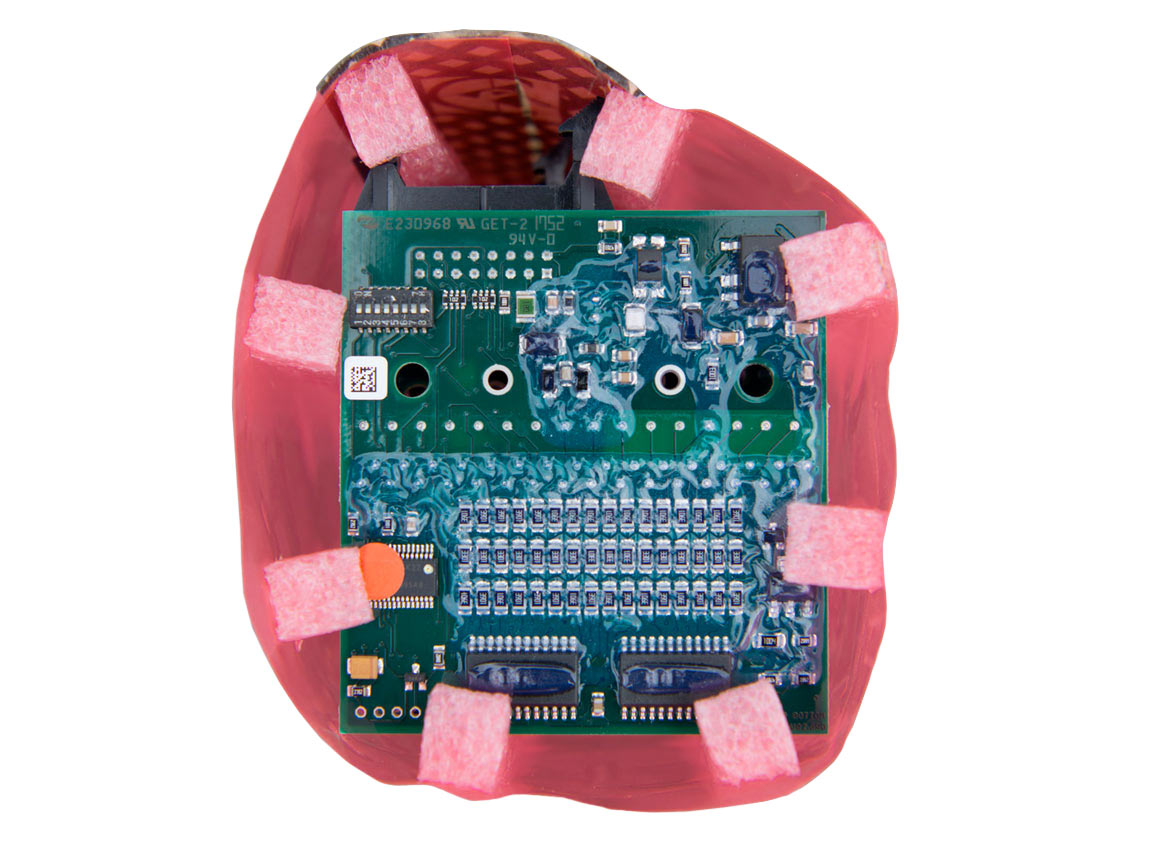

Undesirable is such a discharge in electrical components, because they are damaged by this. Often the charging of such components finds its cause in occurring frictional electricity. Due to their low strength, many electrostatic discharges cannot even be perceived by humans. Nevertheless, they are sufficient to damage electronic components. In the worst case, these are destroyed or the service life of the parts is considerably shortened.

Both during the production and processing of electrostatically sensitive components, as well as during their transport, it must therefore be ensured that no unwanted discharge occurs.

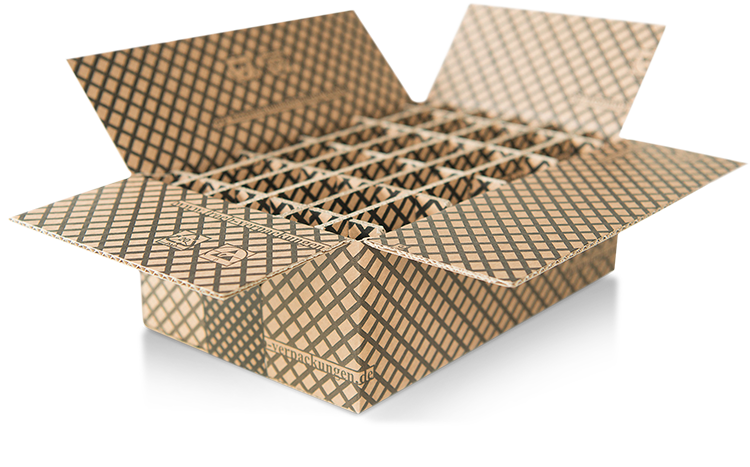

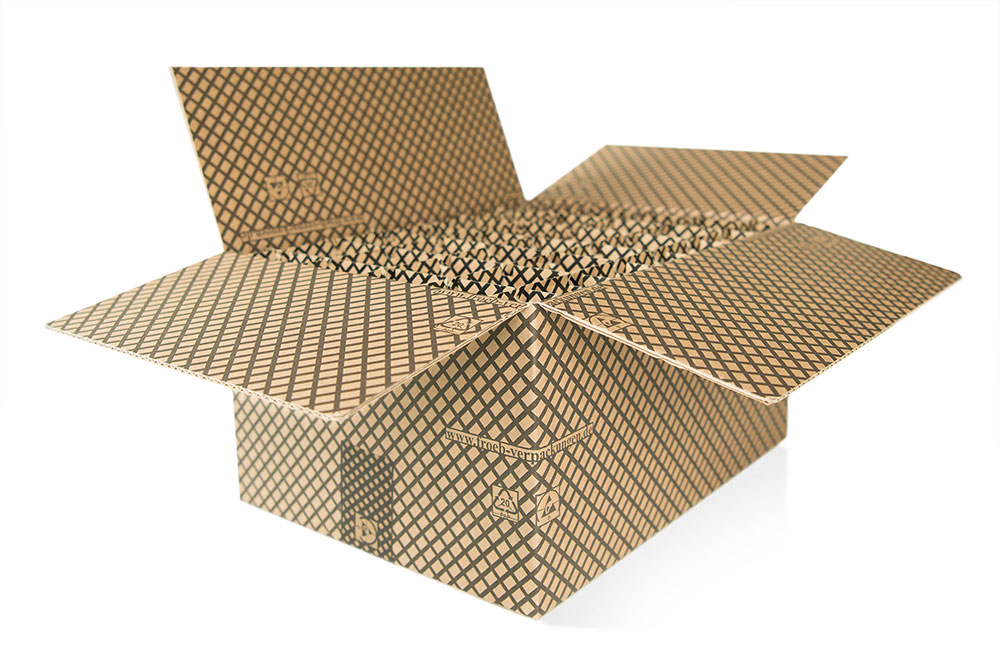

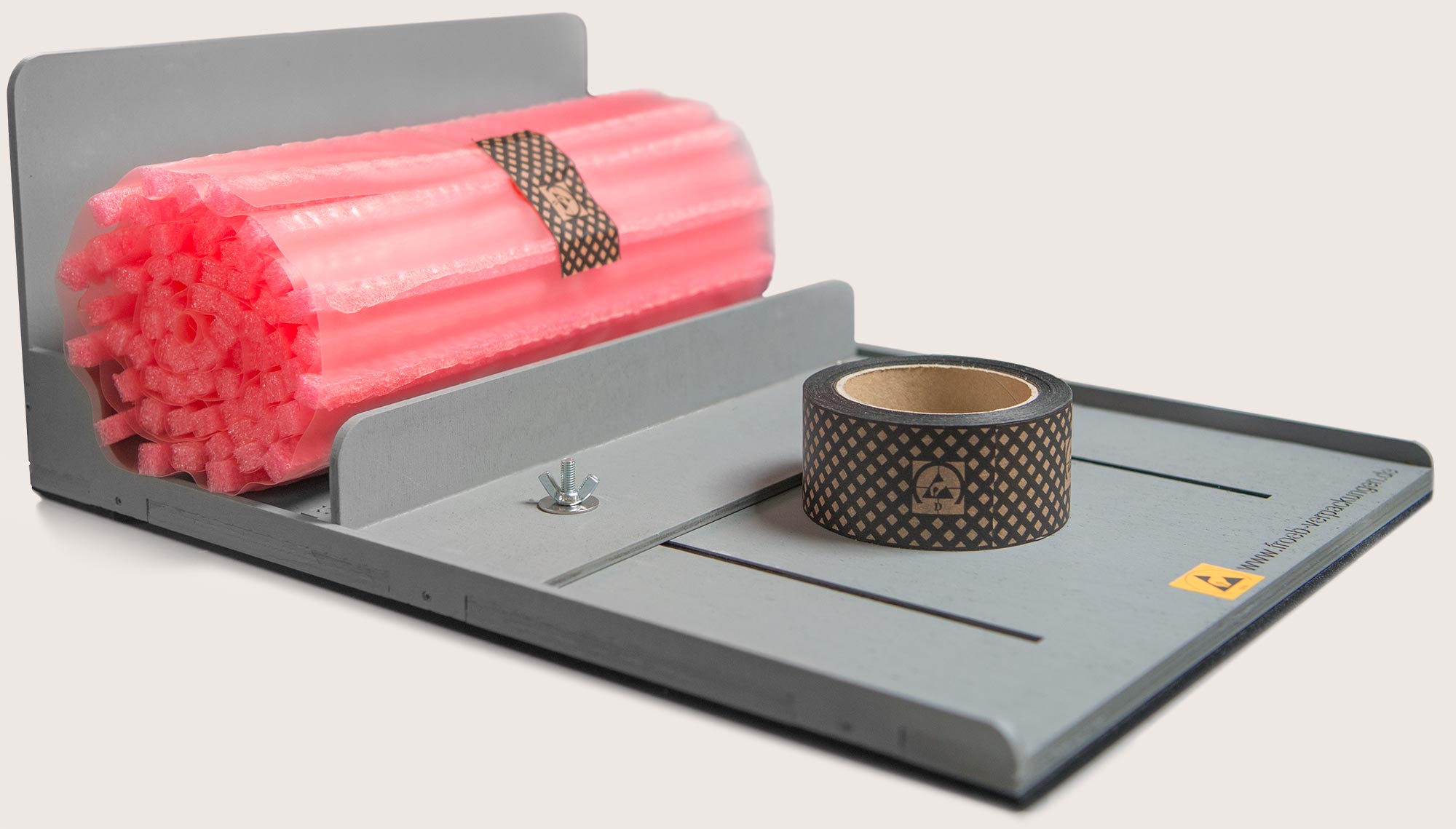

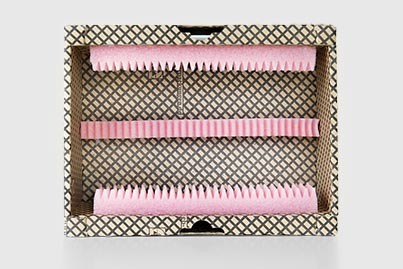

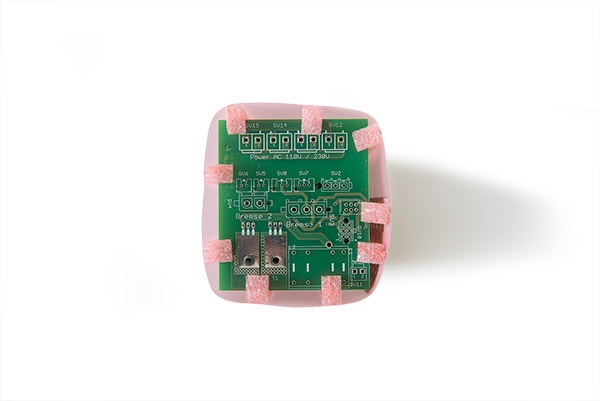

Special antistatic packaging has been designed to protect against this. These are produced from electrically conductive materials in order to discharge any charges that arise from the packaging surface. Mostly it concerns thereby conductively equipped plastic packing. Here, a conductivity of films, filling materials and foams can be produced, for example, by fillers or a metal vapor deposition.

The specific provisions on ESD-compatible packaging can be found in DIN EN 61340-5-3, where the standardization includes the properties and requirements for the classification of packaging used for ESD-sensitive components. The purpose is to avoid charging and discharging too quickly. Therefore, ESD packaging is divided into "conductive" (C), "dissipative" (D) and "shielding" (S). In addition, the protection factor of ESD packaging is classified as low, medium and high.

order sample